Project Description

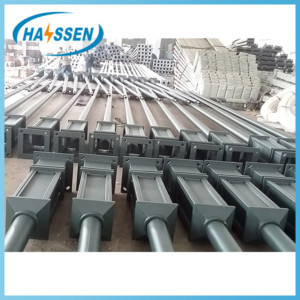

Decorative Lamps Poles

Geneal Information:

| Product Name: | Decorative Lamp Pole Powder Coating With Special Style | |||||||

| Model Number: | 8-12m | |||||||

| Brand Name: | Hanssen | |||||||

| Place of Origin: | Yixing,China | |||||||

| MOQ: | 1 container | |||||||

| Price: | Negotiation | |||||||

| Packing Details: | According to customer’s request | |||||||

| Delivery Time: | Generally speaking,about two weeks after received customers payment | |||||||

| Payment Terms: | T/T, L/C at sight | |||||||

| Product Name: | Decorative Lamp Pole Powder Coating With Special Style | Application: | • Street/Roadway lighting • Residential district • Commercial subdivisions • Industrial zone • Parking lot • Shopping centres • Pathways |

|||||

| Material | Q235B (SS400), Q345B(ASTM A572 Gr.50) |

Shape: | Conical,octagonal,tapered round | |||||

| Surface Treatment: | Hot Dip Galvanization with

/without powder coating |

HDG Standard: | GB/T 13912-2002 or ASTM A 123 |

|||||

| Welding Standard: | GBT 12467.2-2009 / AWS D 1.1 / BS EN 1011-1 |

Service Life Time: | more than 30 Years | |||||

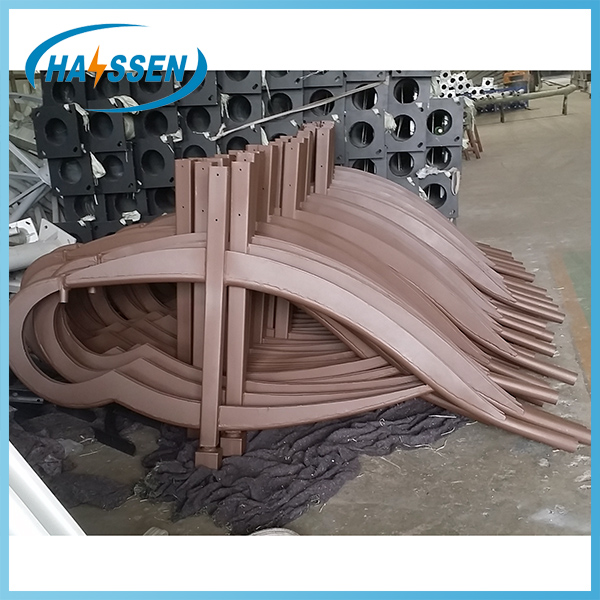

Decorative lamps pole:based on the basic function of lighting up the road,poeple find that they can make the street lighting poles more beautiful which is called decorative lamps pole.This type of poles can be designed with different style to make the street or road different with other places and make the city more beautiful. The decorative lamps pole can be choosed from steel plate, aluminum or other material,and powder coated with different colors.If you interest in this pole,plz feel free to ask more informations from us.

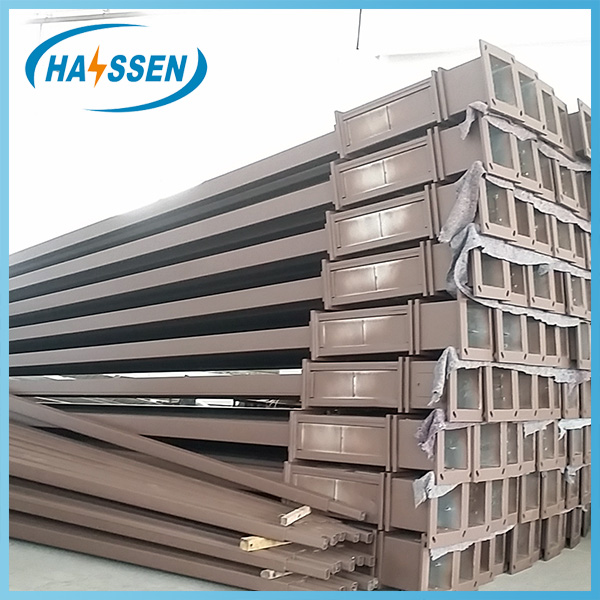

Normally,we welding the decorative lamps poles with submerge-arc welding and CNC welding with beautiful welding line and good quality,we strickly control the test the welding by the flaw testing with ultrasonic crack detection to make sure there is no crack、undercut、slag inclusion、hole vent for the welding. With the good control,we proud to say that our products always wins our customer’s appreciation for our quality.

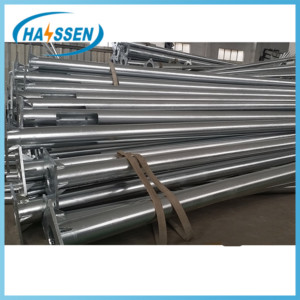

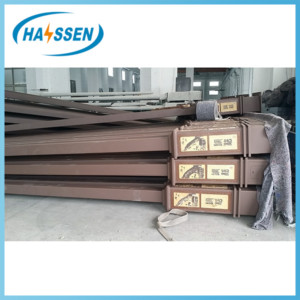

hot dip galvanization

Powder Coating

Standard:GB/T 13912-2002 or ASTM A 123

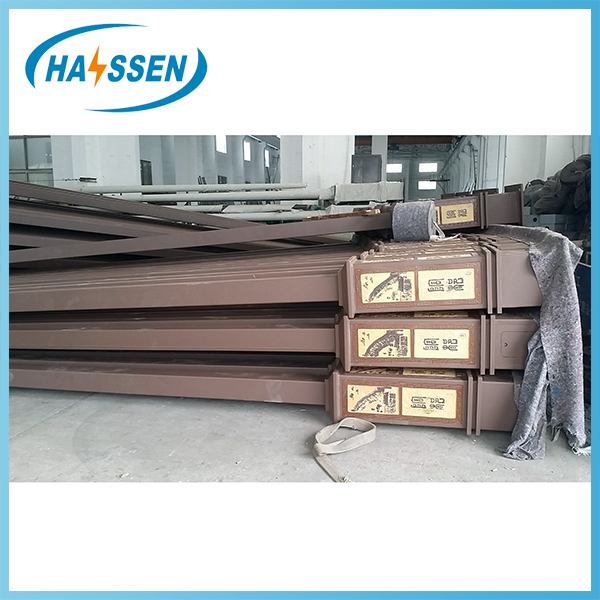

Both outside and inner side of the decorative lamps poles are treated with acid cleaning firstly,then been moved into the zinc pools with more than 450°C temperature completely.At last,the decorative lamps poles are finished the galvanization progress for the anti-corrosion disposal after the passivation,phosphorization which can be continually protect the decorative lamps poles without corrosion more than 30 years.Our standard for a good hot dip galvanization steel mast is same color of the zinc coating without dent mark,no exposed iron and hang of zinc of defect. Normally speaking,the thickness of the zinc coating is up to the materials thickness.The thicker the material is, the thicker the zinc coating will be.

- Ater hot dip galvanization,the decorative lamps poles should been rechecked for the hot dip galvanization

- Then should been Straightening to keep it’s straightness .

- Remove or repair the decorative lamps poles if there’s any defects

- Install the accesseries if there is needed

- Pack the mast accordingly

- Loading for delivery